Roller Brake Test Explained

Understanding HGV Roller Brake Tests: A Comprehensive Guide to Ensuring Vehicle Safety

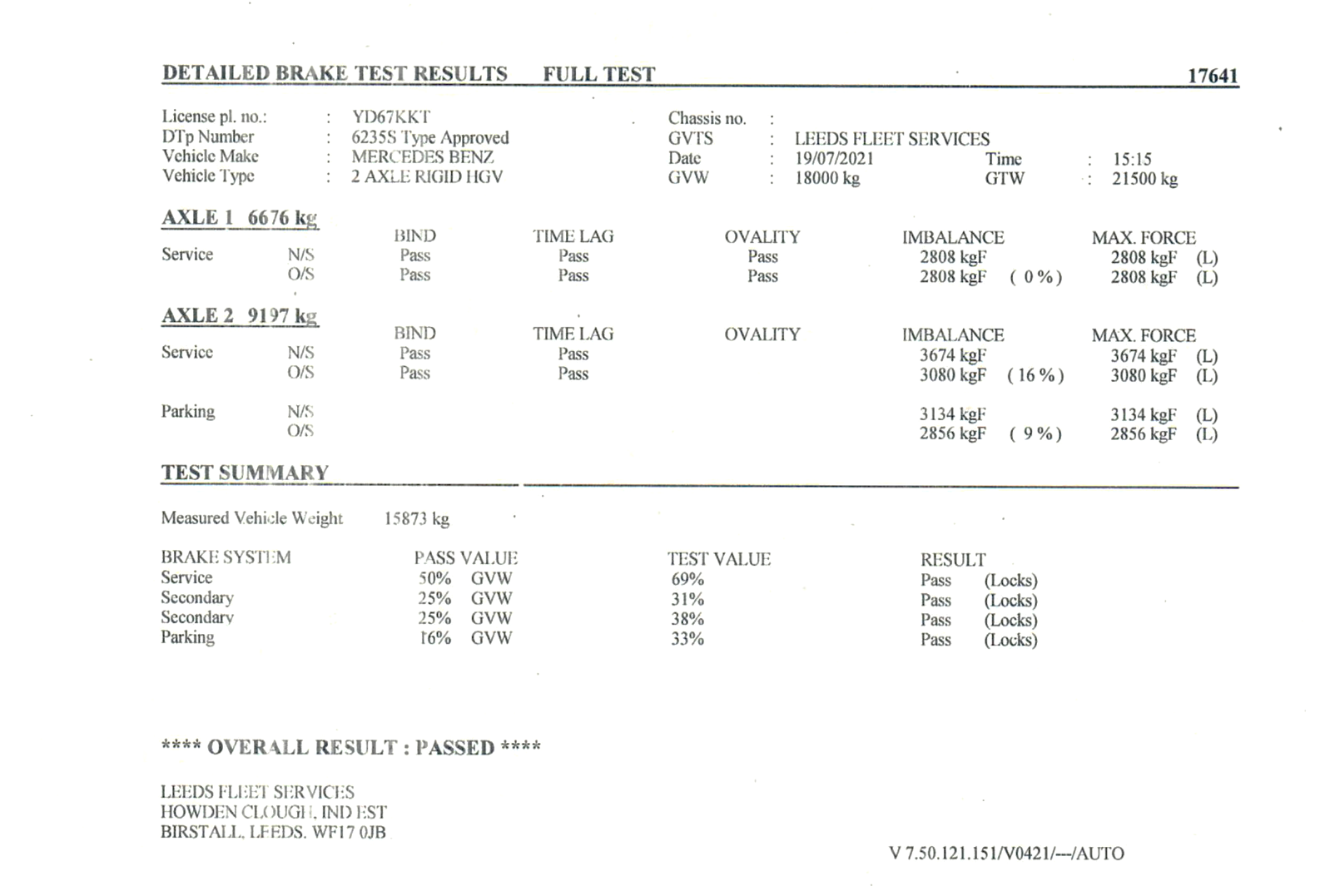

Breaking Down the Roller Brake Test Report: Key Components Explained

Starting in April 2025, it will be mandatory for all safety inspections to either perform a laden brake test or evaluate an Electronic Brake Performance Monitoring System (EBPMS) report if the vehicle or trailer is equipped with one. This change is prompted by Traffic Commissioners (TCs) urging operators to adhere to legal obligations, ensuring that brake maintenance meets satisfactory standards.

ROLLER BRAKE TEST REPORT EXPLAINED STEP-BY-STEP

Lets look at each element and what they mean:

BIND TIME LAG OVALITY IMBALANCE MAX FORCE

Vehicle Identification

DTp Number: This unique identifier links your vehicle to its official documentation and test history. Think of it like a personal identification number for your truck. The accuracy of DTp number (Department for Transport (DfT)) is crucial for accurate brake testing. It acts as a bridge between the vehicle and the DVSA computer, fetching all the necessary information for a compliant and meaningful test. However, there are indeed potential issues that can arise:

False test passes: An HGV failing to meet certain safety standards might pass due to incorrect weight limits or test procedures. Unnecessary test failures: Conversely, a perfectly safe HGV could fail due to overly stringent parameters meant for a heavier or differently configured vehicle. Data integrity issues: In rare cases, a system glitch or human error might cause the DVSA computer to misinterpret the entered DTp number, leading to similar problems as described above.

Outdated data: If the DVSA database hasn't been updated with recent modifications or repairs, the retrieved information might be incomplete or inaccurate, impacting the test's effectiveness. Missing model-specific details: For newer or less common HGV models, the database might not have all the necessary specifications, potentially leading to incomplete tests or inaccurate results.

Safety risks: Inaccurate testing puts both the HGV and other road users at risk by potentially allowing unsafe vehicles to operate or unnecessarily restricting safe ones. Compliance issues: Operating an HGV with a failed brake test due to DTp number errors can lead to fines and legal repercussions.

Double-check the DTp number: Ensure it matches the one on the vehicle's plating certificate. Report any discrepancies: If you suspect an error, inform the testing station and the DVSA immediately. Regular updates: Encourage HGV operators to keep their vehicle information updated with the DVSA.

Weight & Measurement

The table shows what is checked during the test and when it will fail.

What is Bind?

How is it Measured?During a roller brake test, each axle of your HGV is individually tested on rollers simulating real-world road conditions. While simulating no brake application, sensors measure the force exerted by each wheel on the rollers. This force, if present, indicates binding.

Why is it Important? Excessive bind has several negative consequences:

What to Do if Bind is Detected: Several factors can cause bind, including worn or seized brake components, misaligned drums or discs, or even issues with the brake actuation system. If you find excessive bind in your HGV's brake test report:

What is Time Lag?

How is it Measured? During a roller brake test, each wheel on your HGV is equipped with sensors that measure the braking force applied and the time it takes for that force to increase. The time lag is calculated for each wheel, compared across the same axle, and reported in the test results.

What is Ovality?

How does ovality affect braking performance? When a brake drum is oval, the brake shoes or pads won't make consistent contact with the entire surface of the drum. This can lead to several problems:

How to detect ovality: There are a few ways to detect ovality:

What is Imbalance?

Imbalance measures the difference in braking force between the left and right wheels on the same axle of your HGV. Ideally, both wheels should contribute equally to slowing down the vehicle. However, various factors can cause one wheel to exert more or less force compared to the other.

How is it Determined? During a roller brake test, each wheel on your HGV is individually tested on rollers that simulate real-world braking conditions. The maximum braking force generated by each wheel is measured, and the imbalance is calculated as the percentage difference between these forces.

Importance for Safety: Brake imbalance directly impacts your HGV's stopping ability and stability during braking. Here's why:

Regular Maintenance: Regular brake inspections and adjustments are essential to prevent and minimise imbalances. Professional Expertise: If you detect an imbalance, consult a qualified mechanic or HGV specialist for diagnosis and repair. Driver Awareness: Be aware of any pulling sensation during braking, which could indicate an imbalance. By staying informed and taking preventive measures, you can ensure your HGV's brakes operate safely and efficiently, contributing to a safer driving experience for everyone on the road.

What is Max Force?

Have a Question?

If you still need help with anything please contact us

Leeds, LS11 5HL

01135348006

Sun: Closed, Mon - Fri 9:00 - 18:00, Sat 9:00 - 16:00